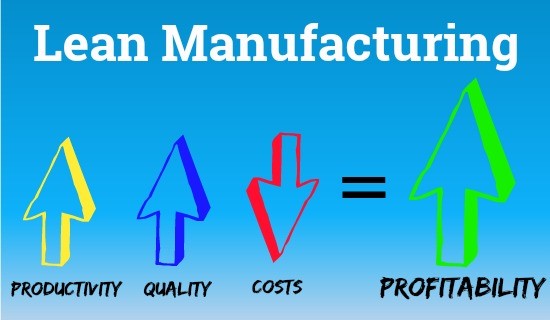

Lean Manufacturing

Value Stream Mapping is a Lean technique for detailed process analysis and design. It captures the key activities of processes and their metrics and focuses on eliminating activities that do not add value to the product or service being developed or delivered.

In Lean Manufacturing it is used to add process cost and time element resources to the process model in order to clearly reveal the flow of materials and products as well as illustrate process efficiency.

In a Manufacturing operation, each team member is taught to focus on ways to reduce wasteful motions or actions – for example, putting tools away exactly where they belong, oriented right side up and in the proper direction for use. Over time, such small steps – communicated to the entire team by individual workers – add up to continuous improvement in productivity, the essence of Lean.

Benefits:

1. Reduction of costs

2. Productivity

3. Quality in products and services

4. Make the kaizen concept alive

5. Seeks improvement in working conditions

6. Strengthens teamwork

7. Less stress, more autonomy

8. Greater satisfaction of people

9. Help view the flow of materials and information

10. Links between the flow of materials and information